| Sign In | Join Free | My portofva.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My portofva.com |

|

Brand Name : THRONCH

Certification : CE.ISO

Place of Origin : China

MOQ : 1 SET

Price : USD 100000-200000 PER SET

Payment Terms : TT / LC,Western Union,MoneyGram

Supply Ability : 10 SET / MONTH

Delivery Time : Depends on the items and the quantity of your order.

Packaging Details : Main body of High Speed Metal Stud and Track Roll Forming Machine is naked and covered by plastic film(to protect of dust and corrosion),loaded into container and steadily fixed in 1x40GP container suitable for long-distance transportation, spare parts are

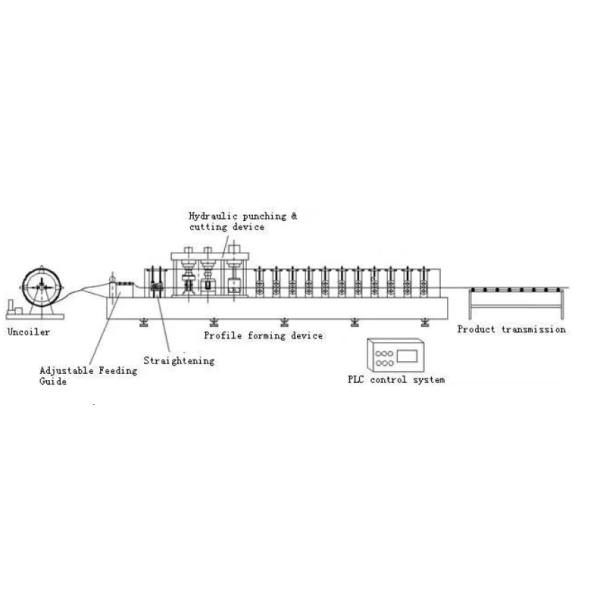

Name : Roll Forming Machine For Brackets with HMI Surface

Process Precesion : ≤ 1 mm

Roller Material : Cr12MoV (SKD11 \ ASTM D2)

Color : Blue/ coustomized

Productionspeed : 20-35 meters per minute

Usage : roofing panel, soalr bracket

Application : Roofing panels, wall panels, door frames, steel profiles

Spindle Material : 40cr AISI 5140 \ DIN 41cr 4)

Diameter Of Shafts : 70/90/100/120 mm

Key Selling Points : Long Service Life

Rolling Width : 100-400mm

Cuttingmethod : Hydraulic Cutting

Main Motor Power : 55kw/75kw

Controlsystem : PLC Control with Touch Screen

| Attribute | Value |

|---|---|

| Material Compatibility | Steel, Aluminum, ZAM |

| Control System | Servo Motor And PLC |

| Horizontal deviation | ± 0.5 mm |

| Longitudinal deviation of hole | ± 0.5 mm |

| Warranty | 1 year |

| Power Supply | 220V, 380V |

| Punching Speed | 300 Punches Per Minute |

| Operation Mode | Automatic |

| Key Selling Points | Long Service Life |

| Parameter | Value |

|---|---|

| Suitable material | Carbon steel, Color steel sheet, galvanized steel sheet |

| Main motor power | 37 or 55 kW with Cycloidal reducer |

| Hydraulic station power | 55kW, 37 kW |

| Hydraulic oil | 40# |

| Thickness | 1.0mm~8.0 mm |

| Diameter | Φ70mm, Φ80mm, Φ90mm... |

| Electric tension | 220V/380V 3phase 50HZ |

| Material of roller | Cr12MoV (Equivalent to SKD11, STD11, D2) |

| Rolling galvanization thickness | 1-3 mm |

| Processing speed | 10-40 m/min |

| Processing precision within | 10m±1.00mm |

| Material of cutting blade | Cr12MoV quenched |

A1: Whole structure, Roller Shaft, Roller Material, Motor & Pump, and Control system. As the new buyer, please kindly know that price is not the final point. Good quality is for long-term business cooperation.

A2: Yes, most of cold roll forming machines need to be customized as per detailed request, because raw material, size, production usage, machine speed, and machine specification will be different.

A3: We can provide the technical offer with FOB, CFR, CIF, Door to Door and so on. Please kindly tell the detailed port name for competitive ocean freight.

A4: Our company adopts 6S system to control every part with passed ISO9001:2000, CE, TUV/BV Certificate.

A5: We provide 12 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.

|

|

Roll Forming Machine For Brackets with HMI Surface Images |